This automatic line, by combining rotary packer and liquid/paste filler is suitable for packing all kinds of liquid and paste, such as syrup, juice, wine, ketchup, bechamel, capsicum paste, scour, liquid milk, liquid detergent,etc.

Features:

1.The machine uses the most stable cam mechanical transmission technology, the equipment is stable, low failure rate, low energy consumption. At the same time the machine uses high-end circuit structure, man-machine interface (PLC + HMI) and other advanced technology to achieve mechanical and electrical integration, easy to operate simple.

2. All controlled by the automated software system to facilitate the functional adjustment and technology upgrades, using the latest German PLC control system. using the CVT transducer.

3. Having self-testing, information feedback, fault display and photoelectric eye tracking. If there is no bag or bag is not open, the machine will not fill and seal, and having real-time display for the running status and automatic shutdown function for emergency. saving packaging materials and raw materials to ensure that the packaging site environment.

4. Adopting imported German engineering plastic bearings without refueling to reduce the pollution of materials.

5. Wide range of packaging material can be used, such as single-layer PE, PE composite material, CPP composite material, aluminum foil, multi-layer composite film, etc.

6. A variety of ways to send bags, bag storage device can store more bags, high rate of bag sending and conveying.

7. Machine operating noise less than 70db.

8. Equipment using constant temperature sealing.

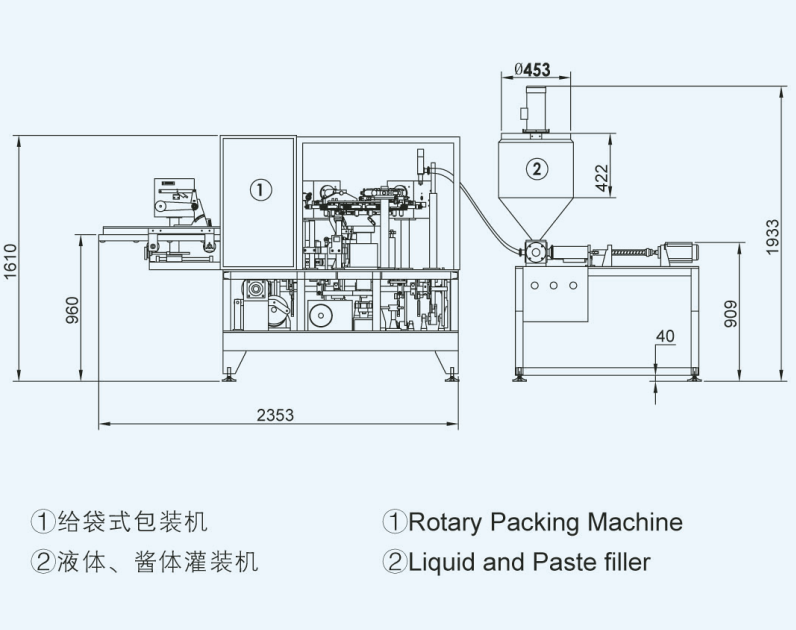

Layout:

*The sizes vary according to models and configurations.

Options:

· Hole-punching device

· Gas flushing device

· Vacuum device

· Flow pouch feeder

· Multiple language

· Inkjet printer

· Pouch folding and labeling device

· Weight checker and metal detector

|

Model |

HNXZ-200 series |

HNXZ-250 series |

HNXZ-300 series |

|

Working positions |

Six/Eight |

||

|

Pouch style |

Flat pouch, stand up pouch, gusset pouch, side spout pouch, etc. |

||

|

Pouch material |

Thermal composite material, such as BOPP/CPP, PET/AL/PE, etc. |

||

|

Pouch size |

L:100-350mm W: 100-210mm |

L: 100-400mm W: 150-260mm |

L: 100-450mm W: 200-300mm |

|

Packing speed |

10-60 pouches/min |

10-50 pouches/min |

10-40 pouches/min |

|

Filling range |

10-3000ml |

||

|

Weighing accuracy |

±0.5-2g |

||

|

Weight |

1000KG |

1200KG |

1300KG |

|

Electric source |

380V 3PH 50/60HZ |

||

|

Power |

2.5KW |

3.5KW |

3.5KW |

|

Air source |

0.65m3/min |

||

*There may be deviations from these specifications due to different configurations.